WEEE Waste Codes Explained: What Your Business Needs to Label Correctly

When it comes to WEEE recycling, most UK businesses focus on arranging a collection and receiving a disposal certificate. But what many overlook is this: the waste code used on your label could be the very thing that leads to rejected collections, failed audits, or even fines.

In this article, we will break down what WEEE waste codes are, why they matter, and how to get them right. No jargon, no legal waffle—just what your team needs to know.

Why WEEE Waste Codes Matter

Every electrical item disposed of by a business in the UK must be classified using the European Waste Catalogue (EWC) or List of Waste (LoW) system. These are six-digit codes that identify what the item is and whether it contains hazardous materials.

These codes dictate how the item is stored, transported, and treated. They are recorded on Waste Transfer Notes, Consignment Notes, and now increasingly in digital systems under upcoming regulations.

Use the wrong code, and the consequences can include:

-

Rejected loads

-

Waste being processed under the wrong permit

-

Enforcement actions by the Environment Agency

-

Invalidation of your duty-of-care documentation

This is not just paperwork. It is legal classification that governs how your waste is handled.

What Are WEEE Waste Codes?

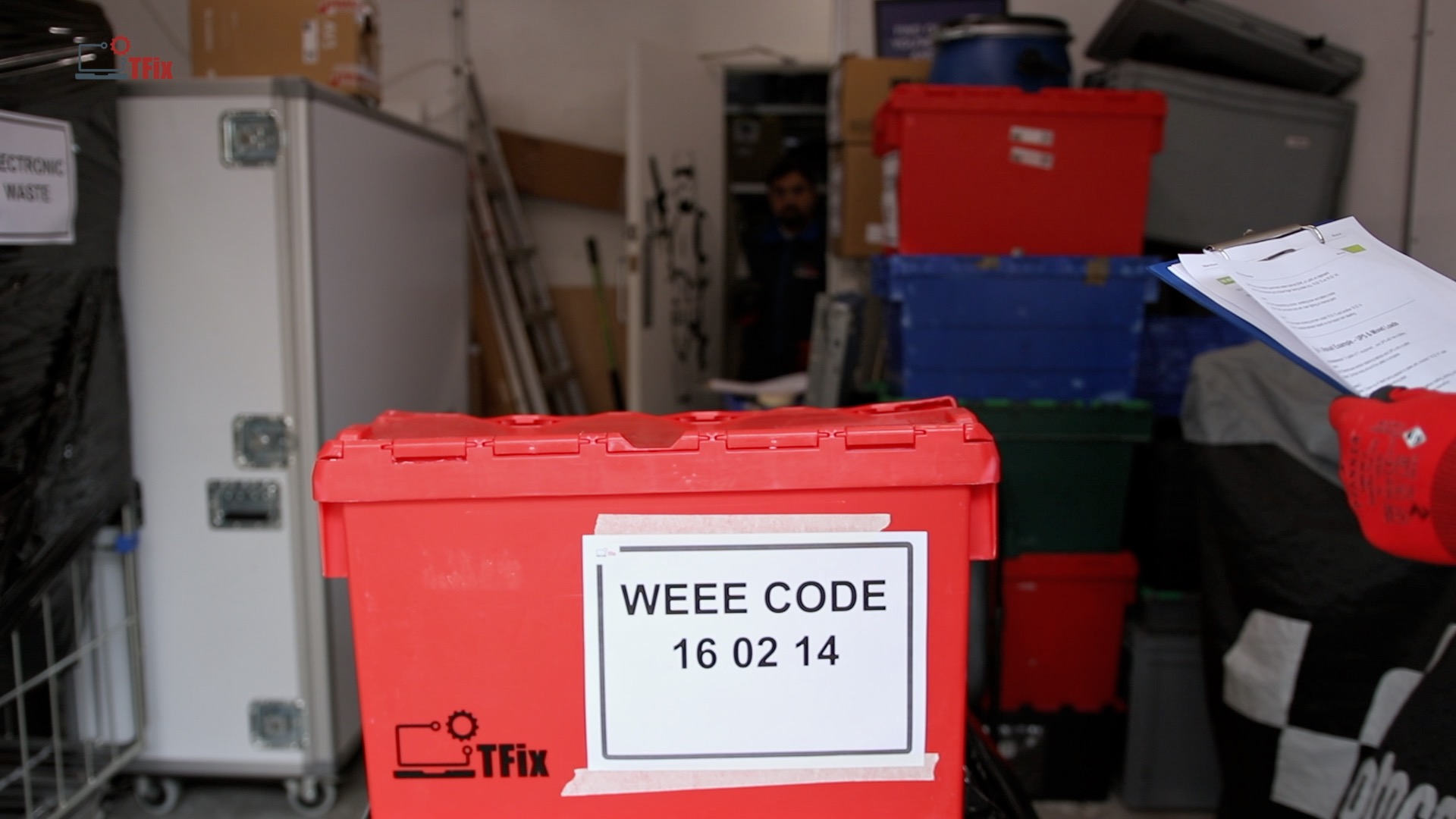

WEEE waste codes fall mostly under the 16 02 category, which covers discarded electrical and electronic equipment. The specific code you choose depends on the components inside the equipment.

For example:

-

16 02 14 – Non-hazardous WEEE (e.g. standard IT equipment with all hazardous elements removed)

-

16 02 13 – Hazardous WEEE (e.g. devices with batteries, toner, or mercury components)

-

20 01 33 – Batteries collected separately

The difference between 16 02 14 and 16 02 13 may seem minor—but it is critical. One digit can determine whether the item is classified as hazardous and subject to different transport and treatment requirements.

A Real-World Example: Mixed Loads

Picture this: You are preparing a pallet of IT assets for disposal. It includes:

-

10 laptops

-

6 monitors

-

2 uninterruptible power supplies (UPS units)

If one UPS still contains a lead-acid battery and you label the whole load as 16 02 14, you have misclassified hazardous waste as non-hazardous. That pallet might be rejected on collection. Worse, it may breach storage or transport regulations if moved under the wrong permit.

It does not matter if 95% of the load is fine. If one item pushes the classification into hazardous territory, the entire batch is affected.

How to Label WEEE Correctly

To stay compliant, make sure each WEEE container, pallet, or bin includes:

-

A clear description of the items

-

The correct six-digit waste code

-

Quantity or estimated weight

-

The date of packaging or labelling

This must match the details entered on your transfer note. If the contents change after the note is issued, a new one should be created.

For mixed loads, it may be necessary to split the items into separate containers with different codes. Grouping hazardous and non-hazardous waste together under a single code is a common and costly mistake.

Common Triggers for Hazardous Classification

Before assigning a code, check whether the equipment contains:

-

Internal batteries (especially lithium or lead-acid)

-

Toner cartridges or ink

-

Mercury backlighting (in older monitors)

-

Capacitors, circuit boards, or refrigerants

If you are unsure, disassemble or inspect the item before labelling. Guesswork does not hold up in an audit.

What Happens If You Get It Wrong

Using the wrong code can cause delays, legal liability, and financial loss. Here is what can happen:

-

Your waste carrier may refuse to collect the load

-

A treatment site may reject the delivery

-

The Environment Agency may issue a warning or fine

-

Documentation may be flagged during an audit as invalid

These issues will only become more visible when Digital Waste Tracking becomes mandatory in the UK from 2026 onward. Every waste movement will be recorded in real-time—making coding errors easier to detect and trace.

Getting Your Process Right

Now is the time to review your internal procedures:

-

Ensure your team knows how to identify hazardous components

-

Cross-reference the correct waste codes before each collection

-

Make sure labels match documentation

-

Prepare for digital compliance

WEEE waste coding is not complex—but it does require attention to detail and consistency. The better your classification, the easier your collections, audits, and downstream compliance will be.

Final Thoughts

Correctly labelling WEEE with the right waste codes protects your business from unnecessary risk. It ensures that electrical waste is stored, transported, and treated legally. And it puts you in a strong position as new digital systems roll out across the UK’s waste sector.

If your team handles IT disposals or electronic waste collections, take time to review your coding process now. It is a small detail that makes a big difference.